It has a complete set of modeling tools and can easily convert 3D models into 2D.

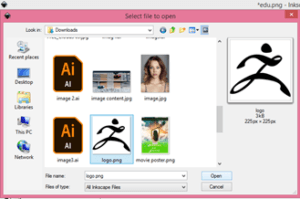

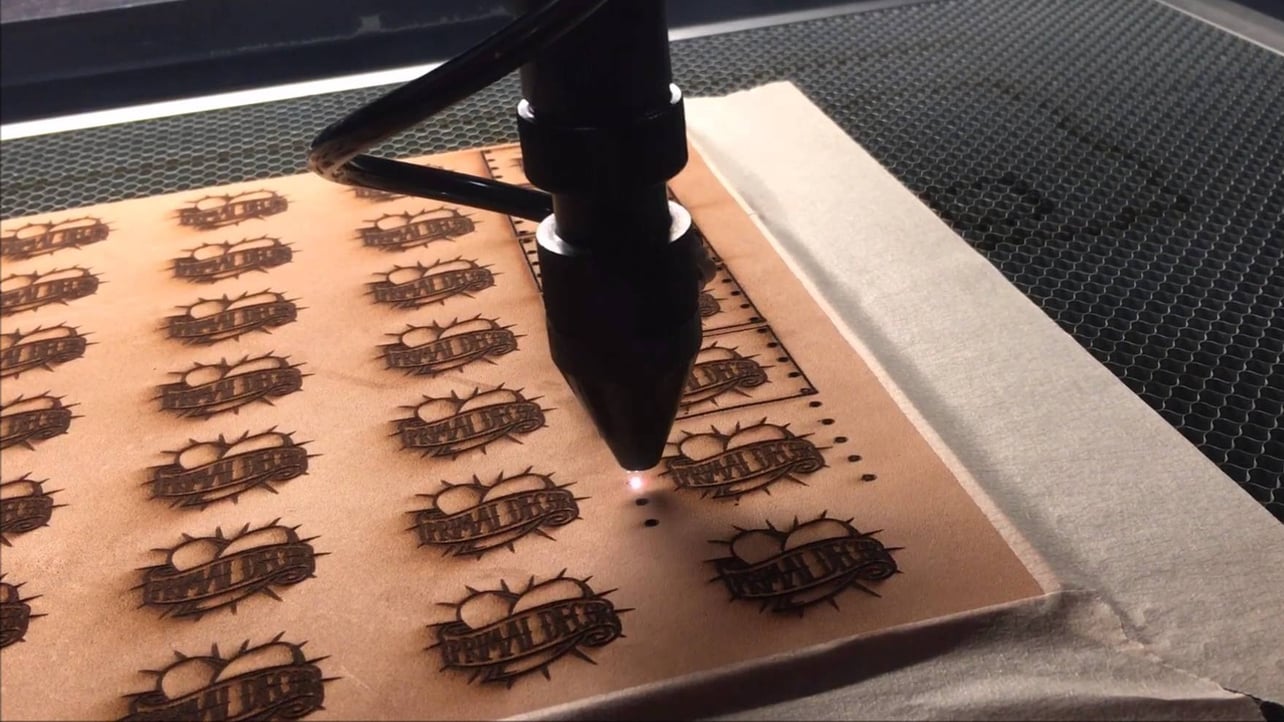

This is then transformed into g-code, the language the CNC machine uses to interpret drawings. A drawing file is created using one of many software packages available - discussed in the next section. This is the principle on which laser cutters operate.

1: Laser Cutting Sheet Metal at KomaspecĬNC stands for Computer Numerical Control. Modern Fibre laser cutting technology is effective in many different materials such as ferrous and non-ferrous metals, plastic, wood, and paper with thicknesses that range from 0.5 mm up to 20+ mm.įig. This burr-free cutting technology can produce accurate and precise cuts up to the order of just a few microns. When it comes to precision fabrication and manufacturing, laser cutting is the top choice.

0 kommentar(er)

0 kommentar(er)